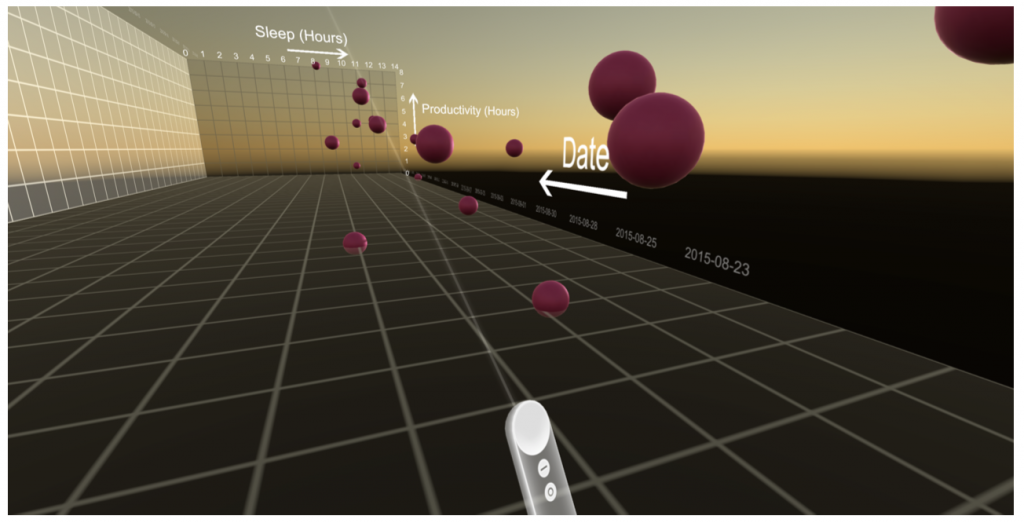

Dr Simon Jones will be presenting his Extended Abstracts paper, “Exploring Data in Virtual Reality”, at the CHI Conference on Human Factors in Computing Systems in Montreal this week. Throughout the LOCM project we have been involved in designing innovative new data visualisations and dashboards to support engineering teams – but what does the future hold for data visualisation and exploration? Virtual Reality (VR) has often been discussed as a promising medium for immersive data visualization. However, few studies have evaluated users’ open-ended exploration of multi-dimensional datasets using VR and compared the results with that of traditional (2D) visualizations. Using a workload- and insight-based evaluation methodology, we conducted a user study to perform such a comparison. We find that there is no overall task-workload difference between traditional visualizations and visualizations in VR, but there are differences in the accuracy and depth of insights that users gain. Our results also suggest that users feel more satisfied and successful when using VR data exploration tools, thus demonstrating the potential of VR as an engaging medium for visual data analytics.

You can read more here: https://researchportal.bath.ac.uk/en/publications/exploring-data-in-virtual-reality-comparisons-with-2d-data-visual