The Language of Collaborative Manufacturing is a £1.9M research project sponsored by the Engineering and Physical Sciences Research Council and led by the Universities of Bristol and Bath in collaboration with our industrial partners. We aim to deliver next-generation project dashboards that can identify potential project issues, improve productivity, and improve the management of aspects such as intellectual property, risk and cost.

LOCM: Where are we now?

During the project we have published more than 40 peer reviewed articles, given numerous presentations and attended a number of national and international exhibitions. Thus, from the perspective of metrics, the project can be considered to have been a great success. But this is not the only perspective to consider. Perhaps the most important one is the positive impact it has had on those involved. In this regard, we have seen two promotions – Dr Watts and Professor Newnes; four new lecturers – Drs Gopsill, Snider, Jones and Joel-Edgar; and four post-docs move into industry – Drs Boa, Emanuel, Shi and Mogles. In addition, this project was for two of our investigators their final major research activity prior to retirement – Professors McMahon and Culley who are both now busier than ever!

Further, while not explicitly follow-on projects the LoCM project has informed and fed into two major new projects:

- EP/R032696/1 – Improving the product development process through integrated revision control and twinning of digital-physical models during prototyping

- EP/R013179/1 – Designing the Future: Resilient Trans-Disciplinary Design Engineers

And, it is great to observe that many of the members of the LoCM project team are now involved in these projects and that the early career academics are establishing their own portfolios and teams. All-in-all a very productive and enjoyable 5 years and a big thank you from me and the whole team to everyone involved and our industrial partners.

If you would like to get in touch with members of the team please contact us through the laboratories at the Universities of Bristol and Bath. Links below.

Design and Manufacturing Futures Laboratory – http://www.dmf-lab.co.uk

Advanced Design and Manufacture @ Bath – http://www.bath.ac.uk/mech-eng/research/advanced-design-and-manufacturing/

LoCM: What have we learnt?

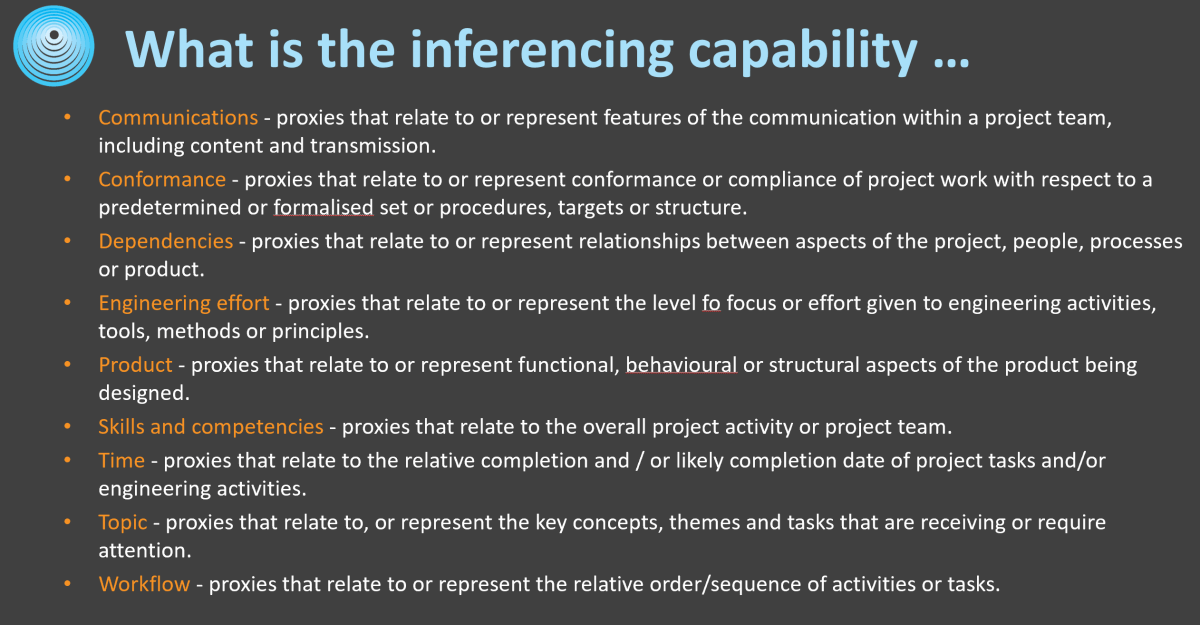

At the outset of the project we hypothesised that we would be able to monitor the evolving digital footprint (emails, reports and models) in order to diagnose and recommend interventions to improve the management of large engineering projects, essentially adding an automated feedback and control loop. So how far did we get? In short, we investigated and characterised the potential inferencing power from the evolving digital footprint; created a suite of algorithms and tools that enable the monitoring of engineering work, project progress and project states; and created dashboards that enabled project managers to drill-down and roll-up through the data to help identify root cause; and, of particular importance to our industrial collaborators, allowed project stakeholders to monitor the impact of the interventions that they had made.

So, did we achieve our initial aim? Yes, but with the important caveat that rather than automating the process of making recommendations or interventions we provide the information and means to interrogate the information in support the professional judgement of the project managers. This approach is consistent with the aim of transforming project managers into evidence-based hypothesis testers where they can explore correlations, changes and the impact of their interventions. While seemingly obvious post facto, such an approach is likely as far as we can go due to the variation in context and situatedness of major engineering – i.e. they are largely one-off and each project is undertaken within a different political, environmental, social and technical context.

Lastly, it is important to note that this project and all of its outputs are intended to support the existing project management toolsets through the provision of real-time information about the project and engineering work. We have shown that additional highly valuable management information can be generated from the evolving digital footprint and characterised the possible inferencing power. For detailed information on proxies, analytics and dashboards please refer to our publications. Alternately, please get in touch with us.

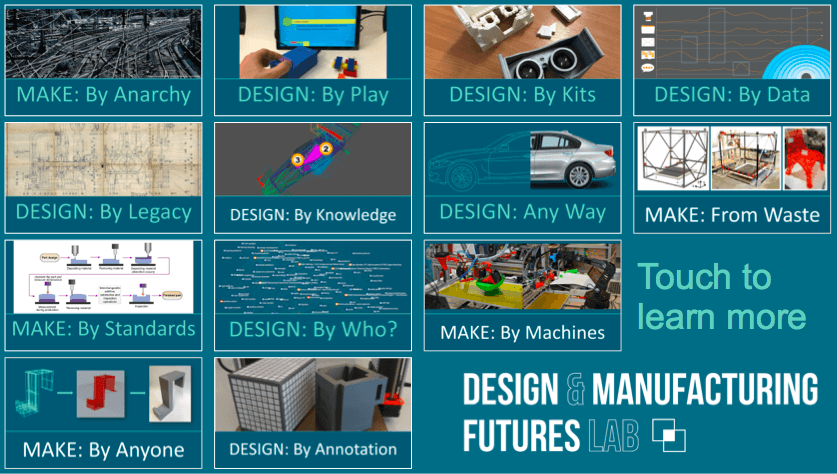

LoCM at Autodesk University

By way of grand finale for the LOCM project some of our research was included in the Design and Manufacturing Futures Lab (http://www.dmf-Lab.co.uk) exhibit at Autodesk’s annual UK/European conference. The event at Tobacco Dock, London, was held between June 19th and 20th and hosted exhibits from all major software vendors and training sessions on Autodesk products. We received over 200 visitors to our stand who were shown vision demonstrators and prototype tools and technologies of the future. Work from the LOCM project was one of ten projects on display. Many thanks to Autodesk for organising such a first class event and to all those who visited us at AU London.

LoCM at Product Lifecycle Management 2018

Congratulations to Dr Snider, Dr Gopsill, and our research intern Harry Whiskard for getting their papers published in Product Lifecycle Management 2018, Turin, Italy.

PLM and PDM systems are a vital tool in engineering companies, and also provide a perfect data source for our analytics. With our work at the cutting edge of analytic capability we are at the forefront of the field, and the conference gave us the perfect opportunity for sharing our work.

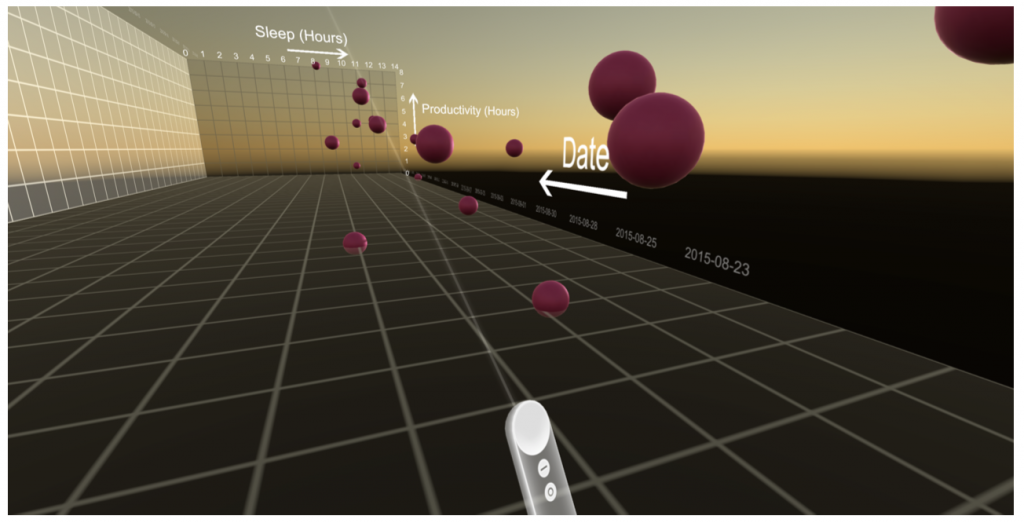

The papers we presented covered a breadth of our analytics and also some of our visualisation work, looking at the future of Virtual Reality (VR) and Augmented Reality (AR) tools in lightweight BIM systems in collaboration with the excellent Altuity Solutions.

Reception for each paper was excellent, with good conversations and opportunities for academic collaboration down the line. Each of the papers can be found at the links:

Engineering Project Health Monitoring: Application of automatic, real-time analytics to PDM systems

Investigating the Evolving Knowledge Structures in New Technology Development

Immersive Data Visualisation in VR

Dr Simon Jones will be presenting his Extended Abstracts paper, “Exploring Data in Virtual Reality”, at the CHI Conference on Human Factors in Computing Systems in Montreal this week. Throughout the LOCM project we have been involved in designing innovative new data visualisations and dashboards to support engineering teams – but what does the future hold for data visualisation and exploration? Virtual Reality (VR) has often been discussed as a promising medium for immersive data visualization. However, few studies have evaluated users’ open-ended exploration of multi-dimensional datasets using VR and compared the results with that of traditional (2D) visualizations. Using a workload- and insight-based evaluation methodology, we conducted a user study to perform such a comparison. We find that there is no overall task-workload difference between traditional visualizations and visualizations in VR, but there are differences in the accuracy and depth of insights that users gain. Our results also suggest that users feel more satisfied and successful when using VR data exploration tools, thus demonstrating the potential of VR as an engaging medium for visual data analytics.

You can read more here: https://researchportal.bath.ac.uk/en/publications/exploring-data-in-virtual-reality-comparisons-with-2d-data-visual

Transdisciplinary Engineers and Researchers

Members of the LoCM team are preparing for an inaugural workshop of the EPSRC Platform grant (see previous news item) to be held at The 25th International Conference on Transdisciplinary Engineering (TE2018) in Modena on July 3rd. To realise the ‘Manufacturing the Future’ utopia, requires ‘Designing the Future’ through the development of tools and competences for future resilient manufacturing; this future builds on the past and present (product and associated service knowledge) but anticipates and predicts the needs of the future by creating a new breed of ‘Trans-Disciplinary Design-Engineer’. This vision needs design and manufacturing researchers to: (1) create a trans-disciplinary suite of tools (e.g. a toolkit depository) and an intellectual framework to support the next- generation 3D/4D additive, traditional subtractive and hybrid manufacturing communities; (2) capture and integrate known design expertise across sectors into a local feed-forward hub to accelerate the integration of new materials, processes and technologies into existing and future products; (3) develop trans-disciplinary engineers (at the boundary of design-manufacturing) to accelerate the ‘manufacturing the future’ outcomes into tangible products and wealth.

In this regard, the workshop will focus on answering the following questions:

- How can we understand and characterise domain specific disruptive change occurring through new manufacturing technologies? And

- How do we rapidly engineer an integrated design and manufacturing tool kit to enable cross-sector uptake of these new technologies?

Inaugural workshop for the Platform grant on Resilient Trans-Disciplinary Design Engineers

Members of the LoCM team capture new award on digital-physical twinning during prototyping

Prof Hicks and Dr Snider have worked with colleagues in the manufacturing division at Bristol to develop a very timely project aiming to create a platform (tools, methods and hardware) that enables the automated twinning and revision control of digital models and physical prototypes during prototyping. The research and technical challenges include: methods for determining and characterising changes to digital models and psychical models, means for automatically constructing/modifying digital models, process planning approaches for hybrid (additive and subtractive) modification of prototypes, and revision control methodologies. The 4 year £1.65M project includes a number of collaborators from the LoCM project (Autodesk and Altuity) and will commence in the summer of 2018. More details can be found here and the project website can be accessed via the Design and Manufacturing Futures Lab website (here).

Members of LoCM lead on £1.8M EPSRC Platform Grant

Members of the LoCM team have been awarded £1.8m by the Engineering and Physical Sciences Research Council (EPSRC) to establish a world-leading research group aimed at designing the engineers of the future.

Led by Professor Linda Newnes, of the University of Bath, the platform brings together academics and researchers from the Universities of Bath, Bristol, and The West of England, and four industrial partners: Airbus Group Ltd, Moog Controls Ltd, Renishaw PLC and Cubik Innovation. The aim of the group is to undertake research to create a pipe-line of “transdisciplinary” design engineers i.e. engineers of the future. This builds upon years of prior work here at the University of Bath in the mechanical engineering, design and manufacturing research group.

A total of 20 academics/researchers will be contributing to the core of the five year platform grant. Future funding will be targeted to sustain the research and early career researchers after 2022, hence a key output for success of the grant is ensuring the development and career progression for each member of the team. Each researcher will be expanding upon their individual career management plan and specific funding is being provided throughout the term of the grant for career advancement activity, training and international secondments.

If you are interested in working with us we currently have an opportunity for a 2-year fixed term research position as well as a funded PhD position (starting October 2018). For further detail of the positions available, or if you would like to become involved with the research, please contact Professor Newnes, L.B.Newnes@bath.ac.uk.

Congratulations to Dr. Gopsill on the EPSRC Researcher in Residence Award

Dr. Gopsill has been awarded an EPSRC Researcher in Residence Award to continue his Knowledge Management work with the National Composite Centre. The project is entitled ‘Valuing Digital Knowledge Assets within the High-Value Manufacturing Catapult’ and will be running over the next 2 years.

Project Summary

The High-Value Manufacturing Catapult (HVMC) Centres are technology intensive organisations whose activities produce innovations and knowledge on a daily basis. Central to these activities is the need to utilise the unique and valuable knowledge that is stored within the digital assets that reside in the IT infrastructure of the centres. Maximising the value of these Digital Knowledge Assets (DKAs) is crucial in ensuring Catapult centres remain at the forefront of innovation and knowledge.

With scoping studies revealing that a large proportion of the National Composite Centre (NCC) DKAs having not been accessed in the past two years, it is contended that unexploited Knowledge Management (KM) opportunities exist in increasing the value of DKAs to support the centres’ activities. Opportunities that could come in the form of developments to the data and information management processes, IT infrastructure and/or knowledge sharing activities. To be able to recognise the added value that these opportunities may bring, a method of assessing the value of DKAs is required.

A method that this proposal will develop by taking the novel approach of monitoring the DKAs’ metadata activity. This step-change in capability will provide actionable information to an organisations’ KM strategy that is both automatic and real-time. The method will also be embedded into the piloting process for developments to KM strategy to assess the potential value they may bring to the organisation.

By understanding and developing a means to assess the value of DKAs, HVMC centres will be able to better leverage the value of their increasing digital footprint as well as ensuring value is added through their KM strategy.

The project starts in April 2018 and you can keep track of his progress on the projects website here.

International Conference on Information Management and Processing

On the 13th January, Sian Joel-Edgar presented a paper entitled “Understanding User Requirements in Context: A Case Study of Developing a Visualisation Tool to Map Skills in an Engineering Organisation” at the International Conference on Information Management and Processing 2018. The conference was held at Imperial College College, London. There were many interesting presentations at the conference, ranging from network analysis of terrorist networks, to artificial intelligence applied to energy, human-machine interfacing and cyber security.

You can view the paper here.